Toyota Corolla (E170): Engine coolant

The coolant level is satisfactory if it is between the “F” and “L” lines on the reservoir when the engine is cold.

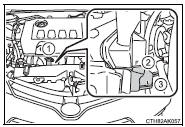

1 Reservoir cap

2 “F” line

3 “L” line

If the level is on or below the “L” line, add coolant up to the “F” line.

■Coolant selection

Only use “Toyota Super Long Life Coolant” or a similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology.

For the U.S.A.: “Toyota Super Long Life Coolant” is a mixture of 50% coolant and 50% deionized water. (Minimum temperature: -31°F [-35°C]) For Canada: “Toyota Super Long Life Coolant” is a mixture of 55% coolant and 45% deionized water. (Minimum temperature: -44°F [-42°C])

For more details about engine coolant, contact your Toyota dealer.

■If the coolant level drops within a short time of replenishing

Visually check the radiator, hoses, engine coolant reservoir caps, drain cock and water pump.

If you cannot find a leak, have your Toyota dealer test the cap and check for leaks in the cooling system.

CAUTION

■When the engine is hot

Do not remove the engine coolant reservoir cap or the radiator cap.

The cooling system may be under pressure and may spray hot coolant if the cap is removed, causing serious injuries, such as burns.

NOTICE

■When adding coolant

Coolant is neither plain water nor straight antifreeze. The correct mixture of water and antifreeze must be used to provide proper lubrication, corrosion protection and cooling. Be sure to read the antifreeze or coolant label.

■If you spill coolant

Be sure to wash it off with water to prevent it from damaging parts or paint.

Other materials:

Circuit description

Refer to dtc p0130

Dtc no.

Dtc detection condition

Trouble area

P0133

After engine has been warmed up, if response time that heated

oxygen sensor’s output voltage reaches from rich to lean.

Or from lean to rich, is 0.6 Second or more during idling.

...

Torque converter clutch and drive plate (atm)

Inspection

1. Inspect torque converter clutch assy

Inspect the one–way clutch.

Set sst into the inner race of the one–way clutch.

Sst 09350–32014 (09351–32010)

set sst so that it fits in the notch of the converter

hub and outer race of the one–way clutch.

...

AHB (Automatic High Beam)

The Automatic High Beam

uses a front camera located

on the upper portion of the

windshield to detect the

brightness of the lights of

vehicles ahead, streetlights,

etc., and automatically

changes the head

lights between the high

beams and low beams.

WARNING

■For safe use

Do not overly rely on the A ...