Toyota Corolla (E120) 2002–2008 Repair Manual / Introduction / Repair instruction / Precaution / Electronic control

Toyota Corolla (E120): Electronic control

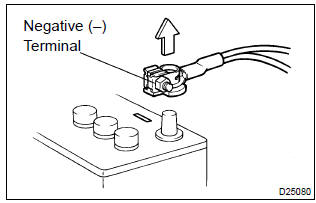

- Removal and installation of battery terminal

- before performing electrical work, disconnect the battery negative (–) terminal cable beforehand so as to prevent burnt–out damage by short.

- When disconnecting and installing the terminal cable, turn the ignition switch and lighting switch off, and loosen the terminal nut completely. Perform these operations without twisting or prying the terminal.

- When the battery terminal is removed, all the memories

of the clock, radio, dtcs, etc. Will be erased.

So before removing it, check them and note them down.

- Handling of electronic parts

- do not open the cover or case of the ecu unless absolutely necessary (if the ic terminals are touched, the ic may be destroyed by static electricity).

- To disconnect electronic connectors, pull the connector itself, not the wires.

- Be careful not to drop electronic components, such as sensors or relays. If they are dropped on a hard floor, they should be replaced and not be reused.

- When cleaning the engine with steam, protect the electronic components, air filter and emission–related components from water.

- Never use an impact wrench to remove or install temperature switches or temperature sensors.

- When checking the continuity at the wire connector, insert the tester probe carefully to prevent terminals from bending.

Other materials:

Do-it-yourself service precautions

If you perform maintenance by yourself, be sure to follow the correct procedure

as given in these sections.

CAUTION

The engine compartment contains many mechanisms and fluids that may move suddenly,

become hot, or become electrically energized. To avoid death or serious injury,

observe t ...

Air outlets

■ Location of air outlets

The air outlets and air volume changes according to the selected airflow mode.

: Some models

■ Adjusting the position of and opening and closing the air outlets

► Front center outlets

Direct air flow to the left or right, up or down.

► Fron ...

Automatic door locking and unlocking systems

The following functions can be set or cancelled:

*1: Vehicles with an automatic transmission or continuously variable transmission

*2: Vehicles with a smart key system

■ Setting and canceling the functions

To switch between set and canceled, follow the procedure below:

1 Vehicles withou ...