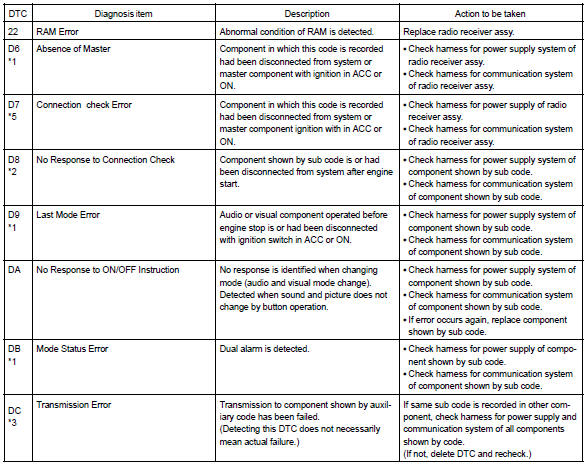

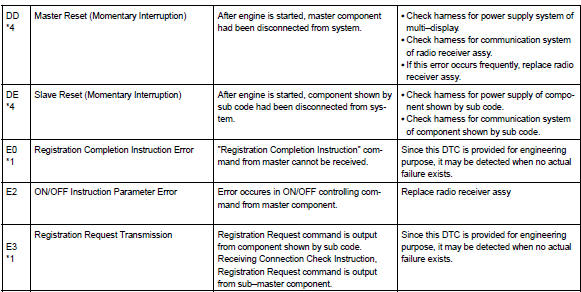

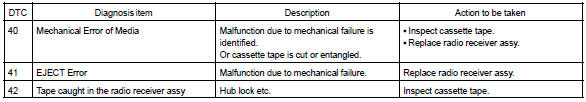

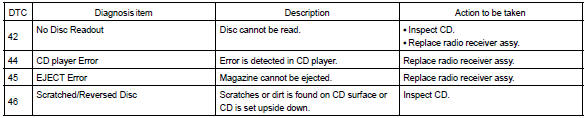

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Audio system / Diagnostic trouble code chart

Toyota Corolla (E120): Diagnostic trouble code chart

|

Terms |

Terms |

| Physical address | Three–digit code (shown in hexadecimal) which is given to each

component comprising

the avc–lan.

Corresponding to the function, individual symbols are specified. |

| Logical address | Two–digit code (shown in hexadecimal) which is given to each function comprising the inner system of the avc–lan. |

1. Radio receiver assy (physical address: 190)

Hint

: *1: even if no failure is detected, it may be stored depending on the battery condition or voltage for starting an engine.

*2: It is stored when 180 sec. Has passed after the power supply connector is pulled out after engine start.

*3: It may be stored when the engine key is turned 1 min. After engine start.

*4: It may be stored when the engine key is turned again after engine start.

*5: When 210 sec. Has passed after pulling out the power supply connector of the master component with the ignition switch in acc or on, this code is stored.

- Logical address: 01 (communication control)

- Logical address: 61 (cassette switch)

- Logical address: 62 (cd player)

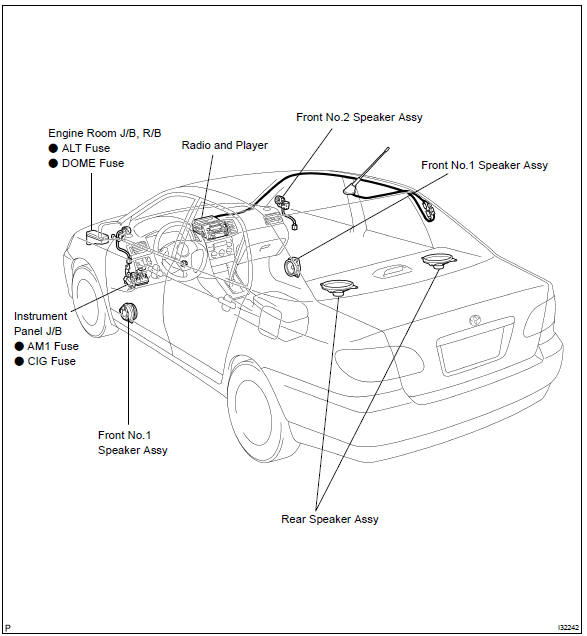

Location

Other materials:

Receiving a phone call

Answering the phone

Press the off-hook switch.

Refusing a call

Press the on-hook switch.

Receiving a call when on another call

Press the off-hook switch.

Pressing the off-hook switch again returns you to the previous call.

Adjusting the ringtone volume when receiving a call

Change the ringto ...

Refueling

Opening the fuel tank cap

Perform the following steps

to open the fuel tank cap:

Before refueling the vehicle

Turn the engine switch off and

ensure that all the doors and

windows are closed.

Confirm the type of fuel.

■Fuel tank opening for unleaded

gasoline

To help prevent incorrect fueling, ...

Source voltage drop

The srs is equipped with a voltage–increase circuit (dc–dc converter) in the

airbag sensor assy center

in case the source voltage drops.

When the battery voltage drops, the voltage–increase circuit (dc–dc converter)

functions to increase the

voltage of the srs to normal voltage.

...