Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Random/multiple cylinder misfire

detected / Confirmation driving pattern

Toyota Corolla (E120): Confirmation driving pattern

- Connect the hand–held tester or the obd ii scan tool to the dlc3.

- record dtcs and the freeze frame data.

- set the check mode using the hand–held tester .

- read the value on the misfire counter for each cylinder when idling. If the value is displayed on the misfire counter, skip the following procedure of confirmation driving.

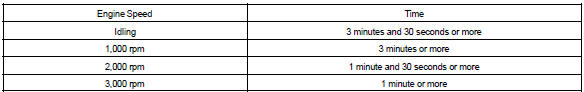

- drive the vehicle several times with the engine speed, load and its surrounding range shown with engine spd, calc load in the freeze frame data or misfire rpm, misfire load in the data list.

If you have no hand–held tester, turn the ignition switch off after the symptom is simulated once. Then repeat the simulation process again.

Hint

: do not turn the ignition switch off during the confirmation driving pattern. This switches the diagnosis system from the check mode to the normal mode, so all the dtcs and freeze frame data will be erased.

- Check whether there is misfire or not by monitoring dtc and the freeze frame data. After that, record them.

- turn the ignition switch off and wait for at least 5 seconds.

Other materials:

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

General information

There are many ecu controlled systems used in the corolla. In general, ecu

controlled system are considered

to be very intricate and require a high level of technical knowledge and expert

skill to troubleshoot.

The fact is, however, that if you proceed by inspecting the circuits one by one, ...

Driving monitor

■ Switching the display

Items displayed can be switched by pressing the “DISP” switch.

■ Average fuel consumption

Displays the average fuel consumption since the function was reset.

• Press and hold the “DISP” switch to reset when the average fuel consumption

is display ...