Toyota Corolla (E120): Circuit inspection

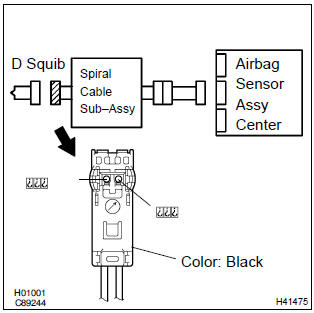

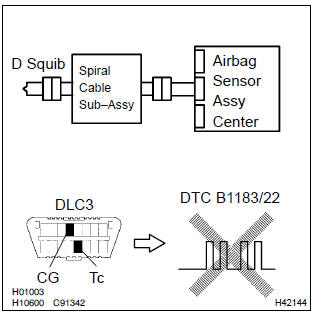

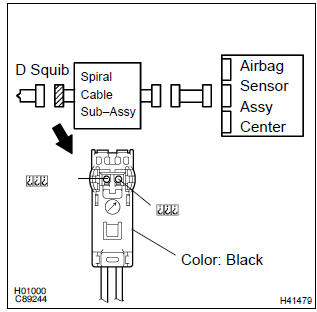

1 Check d squib circuit(airbag sensor assy center – horn button assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the horn button assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

- for the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d2+ and body

ground.

Ok: voltage: below 1 v

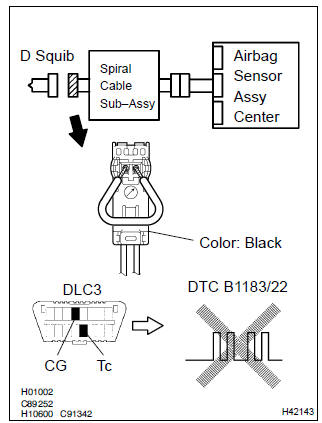

2 Check air bag sensor assy center

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

- using a service wire, connect d2+ and d2– of the black connector (on the spiral cable sub–assy side) between the horn button assy and the spiral cable sub–assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1183/22 is not output.

Hint

: codes other than code b1183/22 may be output at this time, but they are not relevant to this check.

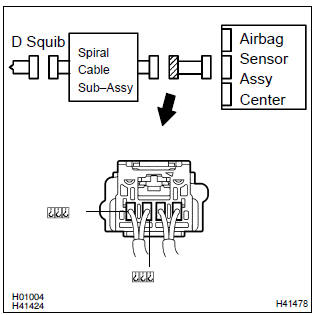

3 Check d squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the horn button assy connectors.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b1183/22 is not output.

Hint

: codes other than code b1183/22 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

5 Check instrument panel wire(airbag sensor assy center – spiral cable sub–assy)

- Turn the ignition switch to lock.

- disconnect the connector of the instrument panel wire.

- turn the ignition switch to on.

- ) for the connector (on the spiral cable sub–assy side) between

the horn button assy and the spiral cable sub–assy,

measure the voltage between d2+ and body ground.

Ok: voltage: below 1 v

6 Check spiral cable sub–assy

- For the black connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d2+ and body

ground.

Ok: voltage: below 1 v

7 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Tire & wheel

Wheel and tire system

Inspection

1. Inspect tire

check the tires for wear and proper inflation pressure.

Cold tire inflation pressure:

Using a dial indicator, check the tire runout.

Tire runout: 3.0 Mm (0.118 In.) Or less

2. Rotate tire

Hint:

see the illustration ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...

Seat belt warning lamp for driver’s seat does not

operate

Wiring diagram

Inspection procedure

1 Check combination meter assy

Ground terminal c9–12 on the combination meter side.

check that the warning lightlights up.

Ok: warning light lights up.

2 Inspect front seat inner belt assy lh

Disconnect the front seat inner belt ...