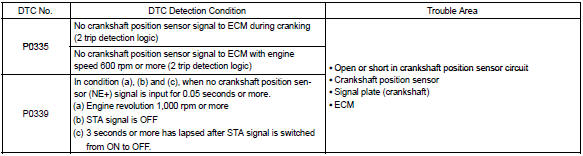

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position sensor ”a”

circuit / Circuit description

Toyota Corolla (E120): Circuit description

The crankshaft position sensor (ne signal) consists of a magnet, iron core and pickup coil.

The ne signal plate (crankshaft position sensor plate) has 34 teeth and is installed on the crankshaft. The ne signal sensor generates 34 signals for each engine revolution. This sensor monitors a plate (timing rotor) located on the crankshaft timing pulley and is used by the ecm to detect crankshaft angle and engine speed (rpm/ne). As the crankshaft timing pulley rotates through an engine revolution, this sensor communicates the rotation of the ne signal plate as a pulse signal to the ecm. Based on the signal, the ecm controls fuel injection time and ignition timing.

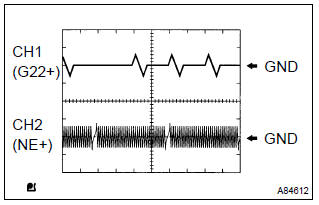

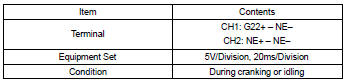

Reference: inspection using the oscilloscope.

Hint

: the correct waveform is as shown on the left.

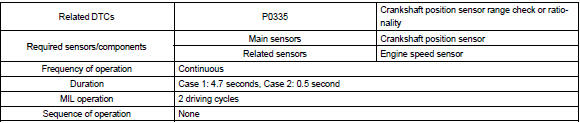

Monitor description

If there is no signal from the crankshaft sensor despite the engine revolving, the ecm interprets this as a malfunction of the sensor.

Monitor strategy

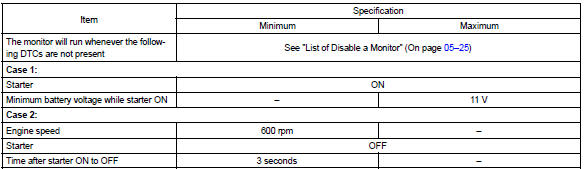

Typical enabling conditions

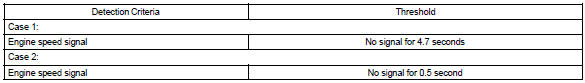

Typical malfunction thresholds

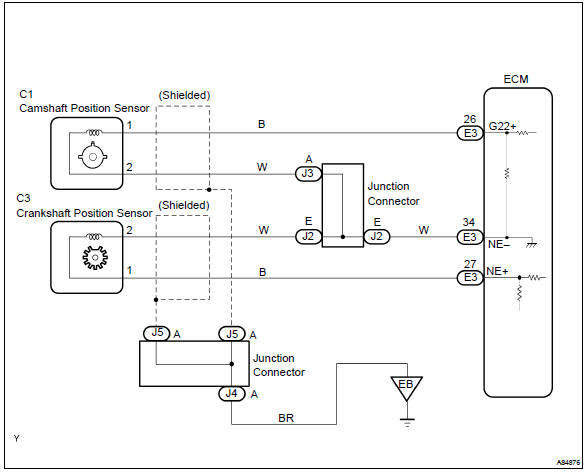

Wiring diagram

Other materials:

Manual air conditioning system∗

Air conditioning controls

► Heater

► Air conditioning system

■ Adjusting the temperature setting

► Heater

To adjust the temperature setting, turn the

dial clockwise to increase the temperature.

► Air conditioning system

To adjust the temperature setting, tu ...

Terminals of ecu

Oscilloscope wave (*1)

Hint:

terminal: od – gnd

gauge set: 5 v / div, 50 ms / div

condition: during cruise control driving o/d switch on.

...

Anti-glare function

► Manual anti-glare inside rear view mirror

Reflected light from the headlights of vehicles behind can be reduced by operating

the lever.

1 Normal position

2 Anti-glare position

► Auto anti-glare inside rear view mirror

Responding to the level of brightness of the headlights of ...