Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Oxygen sensor circuit no activity

detected / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0130

|

Dtc no. |

Dtc detecting condition |

Trouble area |

| P0134 | After engine is warmed up, heated oxygen sensor (bank 1

sensor 1) output does not indicate rich (greater than 0.45 V)

even once when conditions (a), (b), (c), (d) and (e) continue for

more than 65 seconds (1 trip detection logic) :

|

|

Hint

: after confirming dtc p0134, check the output voltage of the heated oxygen sensor (bank 1 sensor 1) in the ”diagnosis / enhanced obd ii / data list / all” using the hand-held tester or the obd ii scan tool.

If the output voltage of the heated oxygen sensor is always less than 0.1 V, the sensor circuit may be open or short.

Monitor description

The ecm uses the heated oxygen sensor to optimize the air–fuel mixture in the closed–loop fuel control.

This control helps decrease exhaust emissions by providing the catalyst with a nearly stoichiometric mixture.

The sensor detects the oxygen level in the exhaust gas and the ecm uses this data to control the air–fuel ratio. The sensor output voltage ranges from 0 v to 1 v. If the signal voltage is less than 0.4 V, the air–fuel ratio is lean. If the signal voltage is more than 0.5 V, the air–fuel ratio is rich. If the sensor does not indicate rich even once despite the conditions for the closed–loop fuel control being met and a specified time period has passed, the ecm will conclude that the closed–loop fuel control is malfunctioning. The ecm will illuminate the mil and a dtc is set.

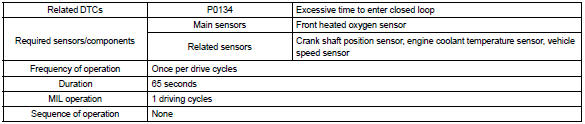

Monitor strategy

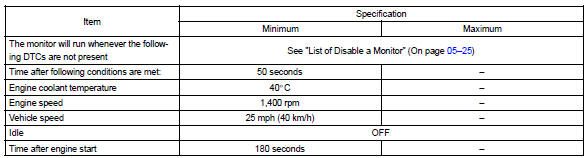

Typical enabling condition

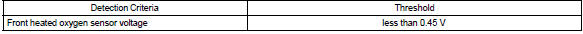

Typical malfunction thresholds

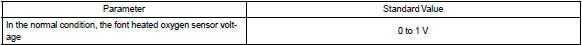

Component operating range

Wiring diagram

Refer to dtc p0130

Other materials:

Replacement

1. Drain brake fluid

Notice:

wash the brake fluid off immediately if it comes into contact with any painted

surface.

2. Remove front wheel rh

3. Remove front fender liner rh

4. Remove brake actuator with bracket

turn the latch of the actuator connector to disconnect the

connector. ...

Overhaul

1. Remove speedometer drive (mtm) gear

Remove the speedometer drive (mtm) gear from the front

differential case.

2. Remove front differential ring gear

Place matchmarks on the front differential ring gear and

front differential case.

Remove the 8 bolts. Using a hamme ...

Inspection procedure

Hint:

read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is

useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the ...