Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position – camshaft

position correlation / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0335

|

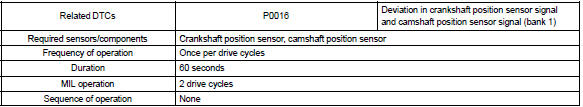

Dtc no. |

Dtc detection condition |

Trouble area |

| P0016 | Deviation in crankshaft position sensor signal and camshaft position sensor signal (2 trip detection logic) |

|

Monitor description

The ecm optimizes the valve timing using the variable valve timing (vvt) system to control the intake valve camshaft. The vvt system includes the ecm, the oil control valve (ocv) and the vvt controller. The ecm sends a target ”duty–cycle” control signal to the ocv. This control signal, applied to the ocv, regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake valve camshaft.

The ecm calibrates the valve timing of the vvt system by setting the camshaft to the maximum retard angle when the engine speed is idling. The ecm closes the ocv to retard the cam. The ecm stores this valve as ”vvt learned value” (when the difference between the target valve timing and the actual valve timing is 5 or less, the ecm learns it).

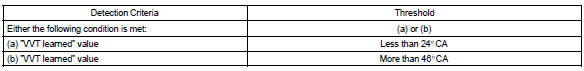

If the learned value meets both of the following conditions (”a” and ”b”), the ecm interprets this as a defect in the vvt system and set a dtc.

- ”vvt learning” value is less than 24 ca, or more than 46 ca.

- above condition continues for more than 18 seconds.

Monitor strategy

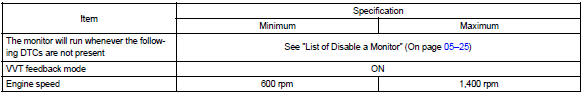

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0335

Other materials:

Trip information

■ Switching the display

Items displayed can be switched by pressing the “DISP” switch.

■ Odometer

Displays the total distance the vehicle has been driven.

Except vehicles with a manual transmission: Press and hold the “DISP” switch

to change the display to the Eco Driving ...

Automatic door locking and unlocking systems

The following functions can be set or cancelled:

*1: Vehicles with an automatic transmission or continuously variable transmission

*2: Vehicles with a smart key system

■ Setting and canceling the functions

To switch between set and canceled, follow the procedure below:

1 Vehicles withou ...

General information

There are many ecu controlled systems used in the corolla. In general, ecu

controlled system are considered

to be very intricate and require a high level of technical knowledge and expert

skill to troubleshoot.

The fact is, however, that if you proceed by inspecting the circuits one by one, ...