Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” actuator

circuit / Circuit description

Toyota Corolla (E120): Circuit description

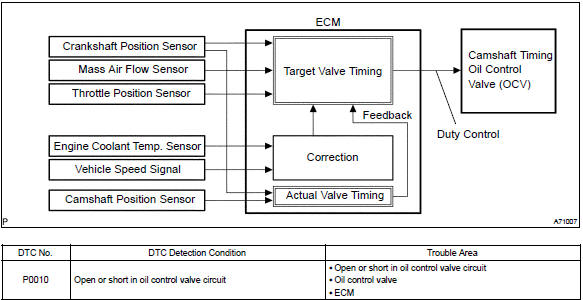

The variable valve timing (vvt) system includes the ecm, the oil control valve (ocv) and the vvt controller.

The ecm sends a target ”duty–cycle” control signal to the ocv. This control signal, applied to the ocv, regulates the oil pressure supplied to the vvt controller. Camshaft timing control is performed based on engine operation conditions such as the intake air volume, throttle position and engine coolant temperature.

The ecm controls the ocv, based on the signals output from the sensors. The vvt controller regulates the intake camshaft angle using oil pressure through the ocv. As result, the relative position between the camshaft and the crankshaft is optimized, and the engine torque improves, fuel economy improves, and exhaust emissions decrease under overall driving conditions. Also, the ecm detects the actual valve timing using signals from the camshaft position sensor and the crankshaft position sensor, and performs the feedback control. This is how target valve timing is verified by the ecm.

Monitor description

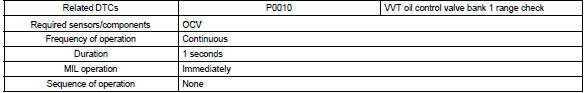

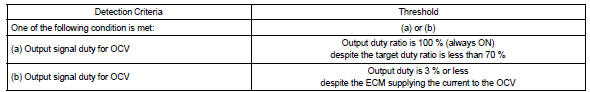

After the ecm sends the ”target” duty–cycle signal to the ocv, the ecm monitors the ocv current to establish an ”actual” duty–cycle. The ecm detects a malfunction and sets a dtc when the actual duty–cycle ratio varies from the target duty–cycle ratio.

Monitor strategy

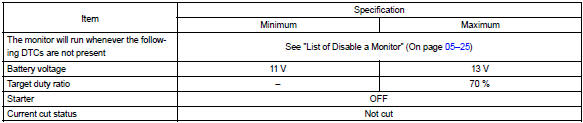

Typical enabling conditions

Typical malfunction thresholds

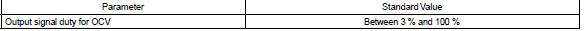

Component operating ra

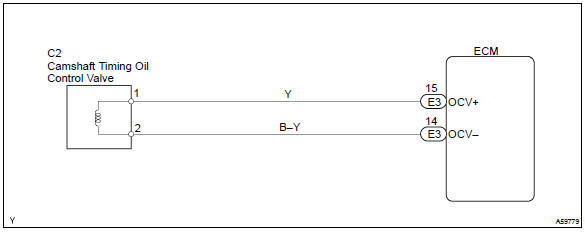

Wiring diagram

Other materials:

Precaution

1. Check that the battery cables are connected to the correct terminals.

2. Disconnect the battery cables when the battery is given a quick charge.

3. Do not perform tests with a high voltage insulation resistance tester.

4. Never disconnect the battery while the engine is running.

5. Check that ...

Replacement

Hint:

installation is in the reverse order of the removal. But the

installation is indicated only when it has a

point.

In the lh side, work in the same procedure as in the rh side.

1. Disconnect battery negative terminal

2. Remove front seat assembly rh

3. Remove front seat inner be ...

Fuel system

Precaution

1. Before working on fuel system, disconnect negative (–) terminal cable

from

battery

2. Do not smoke or work near an open flame when working on fuel system

3. Keep gasoline away from rubber or leather parts

4. Work for prevent gasoline from spilling out

Remove the rear s ...