Toyota Corolla (E120): Check and replace ecu

Notice

: start an inspection of the connector from the backside of the connector on the wire harness side with the connector connected to the ecu.

When no measurement condition is specified, perform the inspection with the engine stopped and also the ignition switch on.

- First check the ecu ground circuit. If it is faulty, repair it.

If it is normal, the ecu could be faulty. In this case, replace the ecu with one that functions normally and check if the symptoms appear.

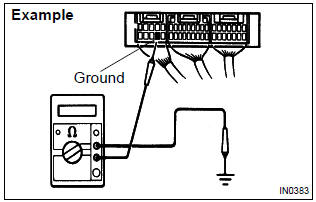

- Measure the resistance between the ecu ground

terminal and body ground.

Resistance: 1 Ω or less

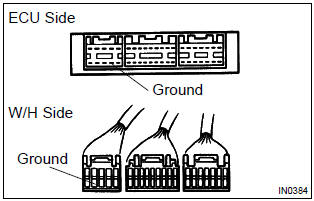

- Disconnect the ecu connector, check the ground terminals on the ecu side and wire harness side for bends and check the contact pressure.

Other materials:

On–vehicle inspection

1. Inspect speedometer

check the operation.

Using a speedometer tester, inspect the speedometer fro allowable

indication error and check

the operation of the odometer.

Reference:

Notice:

tire wear and tire over or under inflation will increase the indication error.

...

Circuit description

The d squib circuit consists of the airbag sensor assy center, spiral cable

sub–assy and horn button assy.

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b1180/17 is recorded when a short is detected in the d squib circuit (2nd

step).

Wiring diagra ...

Ecm (1zz–fe)

Replacement

1. Disconnect battery negative terminal

2. Remove glove compartment door assy

3. Remove ecm

Remove the 2 clips using a clip remover. Then, open the

cover.

Disconnect the 4 ecm connectors.

remove the wire harness from the wire harness clamp.

Remove the 2 ...