Toyota Corolla (E120): Basic inspection

When the malfunction is not confirmed in the dtc check, troubleshooting should be carried out in all the possible circuits considered as causes of the problem. In many cases, by carrying out the basic engine check shown in the following flowchart, the location causing the problem can be found quickly and efficiently. Therefore, using this check is essential in the engine troubleshooting.

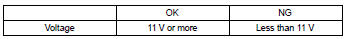

1 Check battery voltage

Notice

: carry out this check with the engine stopped and ignition switch off.

Ng charge or replace battery

2 Check if engine will crank

Ng proceed to problem symptoms table on page

3 Check if engine starts

Ng go to step 7

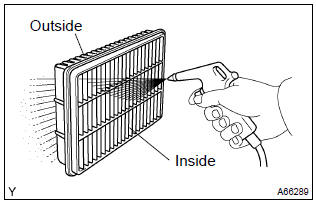

4 Check air filter

- Visually check that the air filter is not excessively dirty or oily.

Notice

: if necessary, clean the filter with compressed air. First blow from the inside thoroughly, then blow from the outside of the filter.

Ng clean or replace

5 Check idle speed

Ng proceed to problem symptoms table on page

6 Check ignition timing

Ng proceed to page 14–1 and continue to troubleshoot

Proceed to problem symptoms table on page

7 Check fuel pressure

Ng proceed to page 11–1 and continue to troubleshoot

8 Check for spark

Ng proceed to page 18–1 and continue to troubleshoot

Proceed to problem symptoms table on page

Other materials:

Replacement

1. Remove engine under cover rh

2. Drain coolant

3. Remove fan and generator v belt

4. Remove generator assy

Disconnect the wire clamp from the wire clip on the rectifire

end frame.

remove the rubber cap and nut, and disconnect the alternator

wire.

disconnect the ...

Optimal use of the multimedia system

On the “Sound Settings” screen, sound quality (Treble/Mid/ Bass), volume balance

can be adjusted.

How to adjust the sound settings and sound quality

1 2 3 Select “-” or “+” to adjust the treble, mid or bass to a level between

-5 and 5.

4 5 Select “Front” or “Rear” to adjus ...

Bluetooth® phone message function

Received messages can be forwarded from the connected Bluetooth® phone, enabling

checking and replying using the multimedia system.

Depending on the type of Bluetooth® phone connected, received messages may not

be transferred to the message inbox.

If the phone does not support the message fu ...