Toyota Corolla (E120) 2002–2008 Repair Manual / Engine control system / Throttle body assy

Toyota Corolla (E120): Throttle body assy

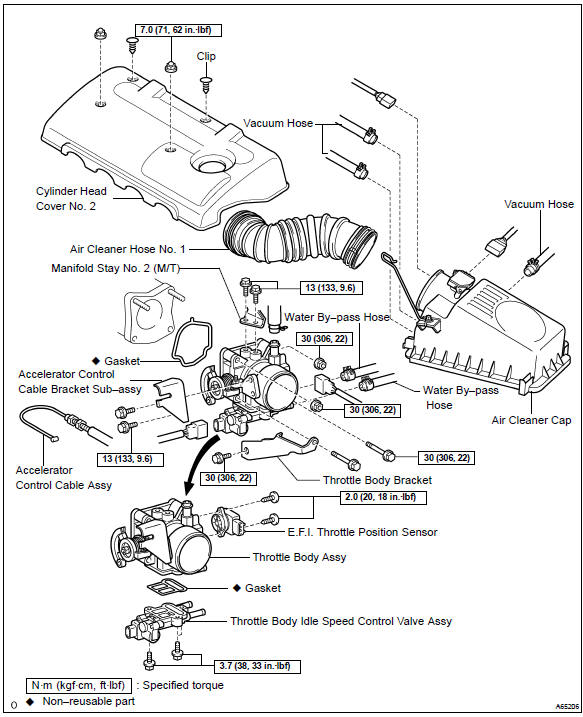

Components

Removal & installation and disassembly & reassembly

1. Drain coolant

2. Remove cylinder head cover no.2

- Remove 2 nuts, 2clips and the cylinder head cover no. 2.

3. Remove air cleaner cap sub–assy

- Disconnect the maf connector.

- disconnect the vsv connector.

- disconnect 3 vacuum hoses, as shown in the illustration.

- loosen an air cleaner hose clump and disconnect an air cleaner hose no. 1.

- remove the air cleaner cap.

4. Remove air cleaner hose no.1

5. Separate accelerator control cable assy

6. Remove throttle body assy

- Disconnect an throttle position sensor connector.

- disconnect a throttle body isc valve assy connector.

- disconnect a pcv hose.

- Disconnect 2 water by–pass hoses.

- Remove 5 bolts, 2 nuts, throttle body bracket and throttle body. (Transaxle m/t)

- Remove 3bolts, 2nuts and throttle body. (Transaxle a/t)

- Remove 2 bolts and accelerator cable bracket.

7. Remove E.F.I. Throttle position sensor

- Remove 2 screws and the throttle position sensor as shown in the illustration.

8. Remove thlottle body idle speed controlvalve assy

- Remove 3 screws and the idle speed control valve assy.

- remove the gasket from the throttle body.

9. Install thlottle body idle speed control valve assy

- Install a new gasket on the throttle body.

- install the idle speed control valve assy with 3 screws.

Torque: 3.7 Nvm (38 kgf·cm, 33 in.Vlbf)

10. Install E.F.I. Throttle position sensor

- Check that the throttle valve is fully close.

- insert the throttle position sensor to the throttle body with it turned counterclockwise by 30 to 90 against the fully close valve position.

- by turning the throttle position sensor clockwise, tighten

2 screws.

Torque: 2.0 Nvm (20 kgf·cm, 18 in.Vlbf)

11. Install throttle body assy

- Install the accelerator control bracket with 2 bolts.

Torque: 13 nvm (133 kgf·cm, 9.6 Ftvlbf)

- Install a new gasket on the intake manifold, as shown in the illustration.

- Install the throttle body with 5 bolts and 2 nuts.(Transaxle

m/t)

torque:

a 30 nvm (306 kgf·cm, 22 ftvlbf) b 13 nvm (133 kgf·cm, 9.6 Ftvlbf)

- Install the throttle body with 3 bolts and 2 nuts.(Transaxle a/t) torque: 30 nvm (306 kgf·cm, 22 ftvlbf)

- Connect 2 water by–pass hoses to the throttle body.

- Connect the pcv hose to the throttle body.

- connect the throttle body idle speed control valve assy connector to the throttle body.

- connect the throttle position sensor connector to the throttle body.

12. Install air cleaner cap sub–assy

- Install the air cleaner cap.

- connect the air cleaner hose.

- Connect 3 vacuum hoses, as shown in the illustration.

- connect the vsv connector.

- connect the intake air flow meter connector.

13. Install cylinder head cover no.2

- Install the cylinder head cover no. 2 With 2 nuts and 2

clips.

Torque: 7.0 Nvm (71 kgf·cm, 62 in.Vlbf)

14. Add coolant

15. Check engine coolant leak

Other materials:

Fog light switch

The fog lights secure excellent visibility in difficult driving conditions,

such as in rain and fog.

1 Turns the front fog lights off

2 Turns the front fog lights on

*1: For U.S.A.

*2: For Canada

■Fog lights can be used when

The headlights are on in low beam. ...

Cargo and luggage

Take notice of the following

information about storage

precautions, cargo capacity

and load:

Capacity and distribution

Cargo capacity depends on the

total weight of the occupants.

(Cargo capacity) = (Total load

capacity) - (Total weight of

occupants)

Steps for Determining Correct

Load Limit -

(1) L ...

Circuit description

The p squib (2nd step) circuit consists of the airbag sensor assy center and

instrument panel passenger

airbag assy.

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b1185/57 is recorded when a short is detected in the p squib (2nd step)

circuit.

Wiri ...