Toyota Corolla (E120) 2002–2008 Repair Manual / Starting & charging / Starting system

Toyota Corolla (E120): Starting system

Inspection

1. Inspect starter assy

Notice

: these tests must be performed within 3 to 5 seconds to prevent burnout of the coil.

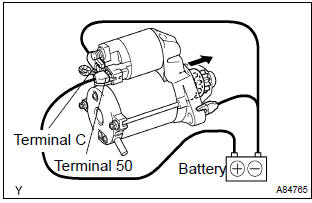

- perform the pull–in test.

- Remove the nut, then disconnect the lead wire from terminal c.

- Connect the battery to the starter repair service kit as shown in the illustration. Check that the clutch pinion gear is extended.

If the clutch pinion gear is not extended, replace the starter repair service kit.

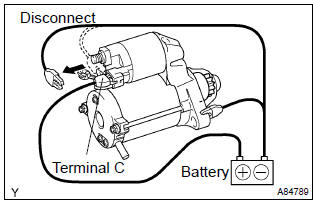

- Perform the hold–in test.

- Disconnect the negative (–) lead from terminal c

with the lead wire disconnected from terminal c.

Check that the clutch pinion gear remains extended.

If the clutch pinion gear returns, replace the starter repair service kit.

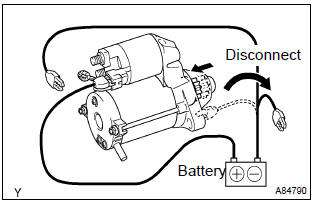

- Check the clutch pinion gear returns.

- Disconnect the negative (–) lead from the starter body. Check that the clutch pinion gear returns.

If the clutch pinion gear does not return, replace the starter repair service kit.

- Perform the no–load performance test.

- Connect the lead wire to terminal c with the nut.

Make sure that the lead is not grounded.

Torque: 10 nvm (102 Kgf·cm, 7 ft·lbf)

- Clamp the starter in a vise.

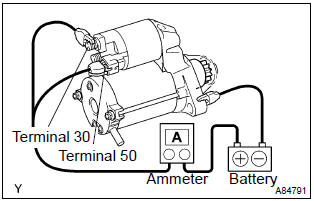

- Connect the battery and an ammeter to the starter as shown in the illustration.

- Check that the starter rotates smoothly and steadily

with the clutch pinion gear extended. Check that the

ammeter reads the specified current.

Specified current: 90 a or less at 11.5 V

If the current is not as specified, replace the starter repair service kit.

2. Inspect starter relay assy

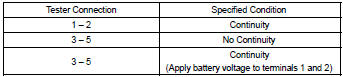

- Check the continuity.

- Using an ohmmeter, check for continuity between each terminal.

Specified condition:

If the result is not as specified, replace the starter relay.

Other materials:

Front door belt moulding assy lh

Replacement

Hint:

the installation procedures are the removal procedures in reverse

order.

Use the same procedures for the rh side and lh side.

1. Remove front armrest assy lh

2. Remove power window regulator master switch assy (w/ power window)

3. Remove front armrest base panel up ...

Replacement

1. Drain engine oil

remove the oil pan drain plug and drain the engine oil.

2. Removal & installation chain sub–assy

3. Remove chain vibration damper no.1

remove 2 bolts and chain vibration damper no. 1.

4. Remove oil pump assy

Remove the 5 bolts.

rem ...

Rear seats

The seatbacks of the rear

seats can be folded down.

Folding down the rear

seatbacks

1. Move the front seats forward.

2. Stow the rear armrest. (if

equipped).

3. Fold the seatback down while

pushing the seatback lock

release button.

Each seatback may be folded separately.

WARNING

Observe the follo ...