Toyota Corolla (E120): Inspection

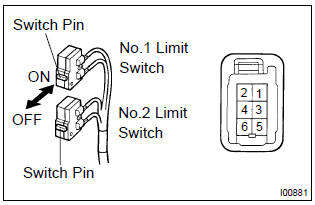

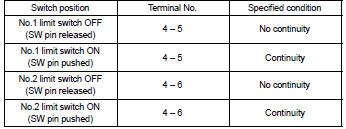

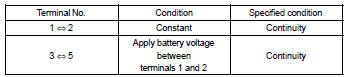

1. Inspect sliding roof limit switch

- Inspect the sliding roof limit switch continuity.

Standard:

If the continuity is not as specified, replace the switch.

2. Inspect sliding roof drive gear sub–assy

- Connect the positive (+) lead from the battery to terminal 2 and the negative (–) lead to terminal 1, and check that the motor turns clockwise (moves to the close side).

- Reverse the polarity, check that the motor turns counterclockwise (moves to the open side).

If the operation is not as specified, replace the motor.

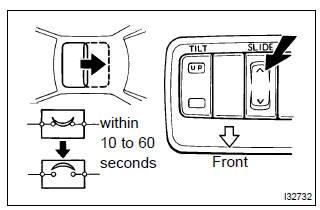

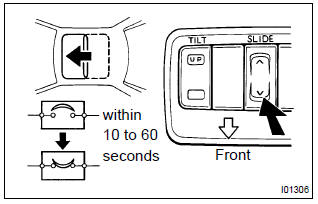

3. Inspect sliding roof motor circuit breaker

- With the sliding roof in the fully opened position, hold the sliding roof switch in the ”open” side and check that there is circuit breaker operating noise within 10 to 60 seconds.

- With the sliding roof in the fully opened position, hold the sliding roof switch in the ”close” side and check that the sliding roof begins to close within 60 seconds.

If the operation is not as specified, replace the motor.

4. Inspect power main relay

- Remove the power window relay from the instrument panel j/b.

- inspect the power window relay.

Standard:

If the result is not as specified, replace the relay.

Other materials:

Disposal

1. Dispose shock absorber assy rear lh

Fully extend the shock absorber rod.

using a drill, make a hole in the cylinder as shown in the

illustration to discharge the gas inside.

Caution:

when drilling, chips may fly out, work carefully.

The gas is colorless, odorless and no ...

On–vehicle inspection

1. Install lspv gauge (sst) and bleed air

remove the bleeder plugs from the front and rear brake cylinder.

install the lspv gauge (sst), and bleed the air.

Sst 09709–29018

2. Raise master cylinder pressure and check rear wheel cylinder pressure

Hint:

when inspectin ...

Replacement

Hint:

installation is in the reverse order of the removal. But the

installation is indicated only when it has a

point.

In the lh side, work in the same procedure as in the rh side.

1. Disconnect battery negative terminal

2. Remove front seat assembly rh

3. Remove front seat inner be ...